Last Drop

The Project Last Drop aims to address the issue of inefficiency in cosmetic tube packaging.

ThE initiative seeks to provide a more effective way of using every bit of the product inside the tube and simplifying the process of opening it.

Instead of needing scissors to cut open the tube, the packaging features a pull tab that helps extract the very "last drop" of the product. This design also aids in the recycling process by allowing the separation of materials before disposal.

Client

Graduate Thesis Project

(MFA Industrial Design)

Year

2024

The Origin

With 2.5 years in cosmetics design, I've seen its environmental impact firsthand.

Initially attracted by creativity, over time I've come to recognize the industry's wasteful practices such as excessive packaging and rapid trend turnover.

Talking Facts

Only 9% of cosmetic waste is currently being recycled, indicating a pressing need for improved sustainability practices within the industry.

Annually, the cosmetics industry contributes to the disposal of over 1.2 billion units of products into landfills.

Over 60% of this packaging still contains unexpired or unused product, underscoring the inefficiency and wastefulness inherent in current cosmetic consumption and disposal patterns.

Recycling programs suggest rinsing packaging before disposal into recycling systems, but only an estimated 20-30 percent of containers are actually rinsed, highlighting low adherence to this recommendation.

Why don't people rinse their packages?

Time & Effort

People often don't rinse their packages due to the extra time and effort it requires.

Product Integrity

Concerns about damaging the packaging or reducing its resale value can deter rinsing.

Appearance

Maintaining the original appearance of the packaging might be important to some consumers.

Material Design

Some packages are not designed for easy rinsing, making the process impractical.

Consumer Behavior

Habitual behaviors and lack of awareness about the benefits of rinsing also play a role.

Market Status

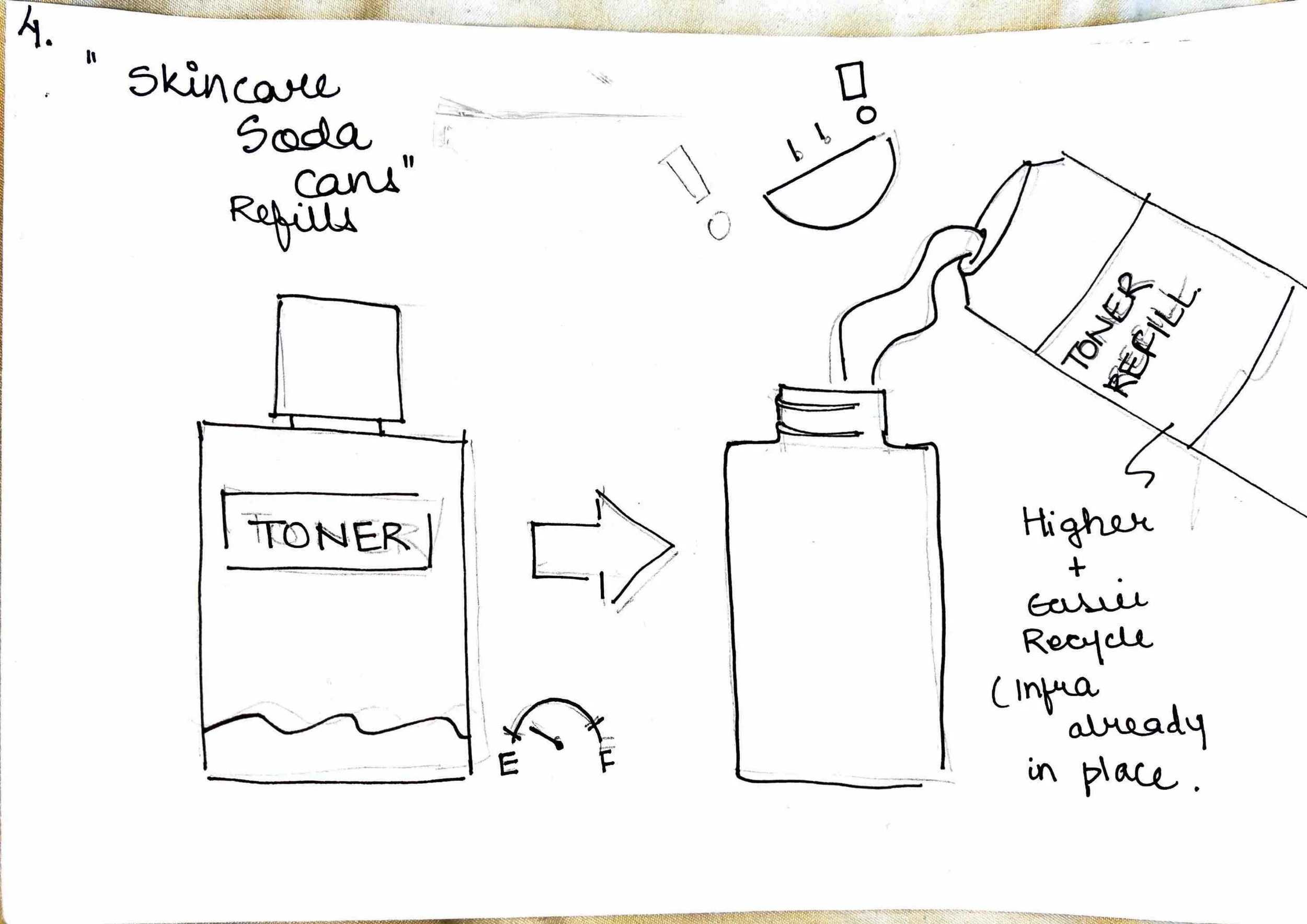

Using concentrates as packaging, brands are cutting shipping costs and environmental impact by using less water in production. This also conserves fuel/energy and resources.

Dove's refillable deodorant features PCR material and promotes retaining the aluminum body for brand loyalty.

Fenty Beauty's refillable jar uses 100% PCR material and refillable cartridges to minimize plastic waste.

Subscription models like BoxyCharm offer travel-sized cosmetics with a "try then buy" approach, reducing wasteful consumption and landfill buildup.

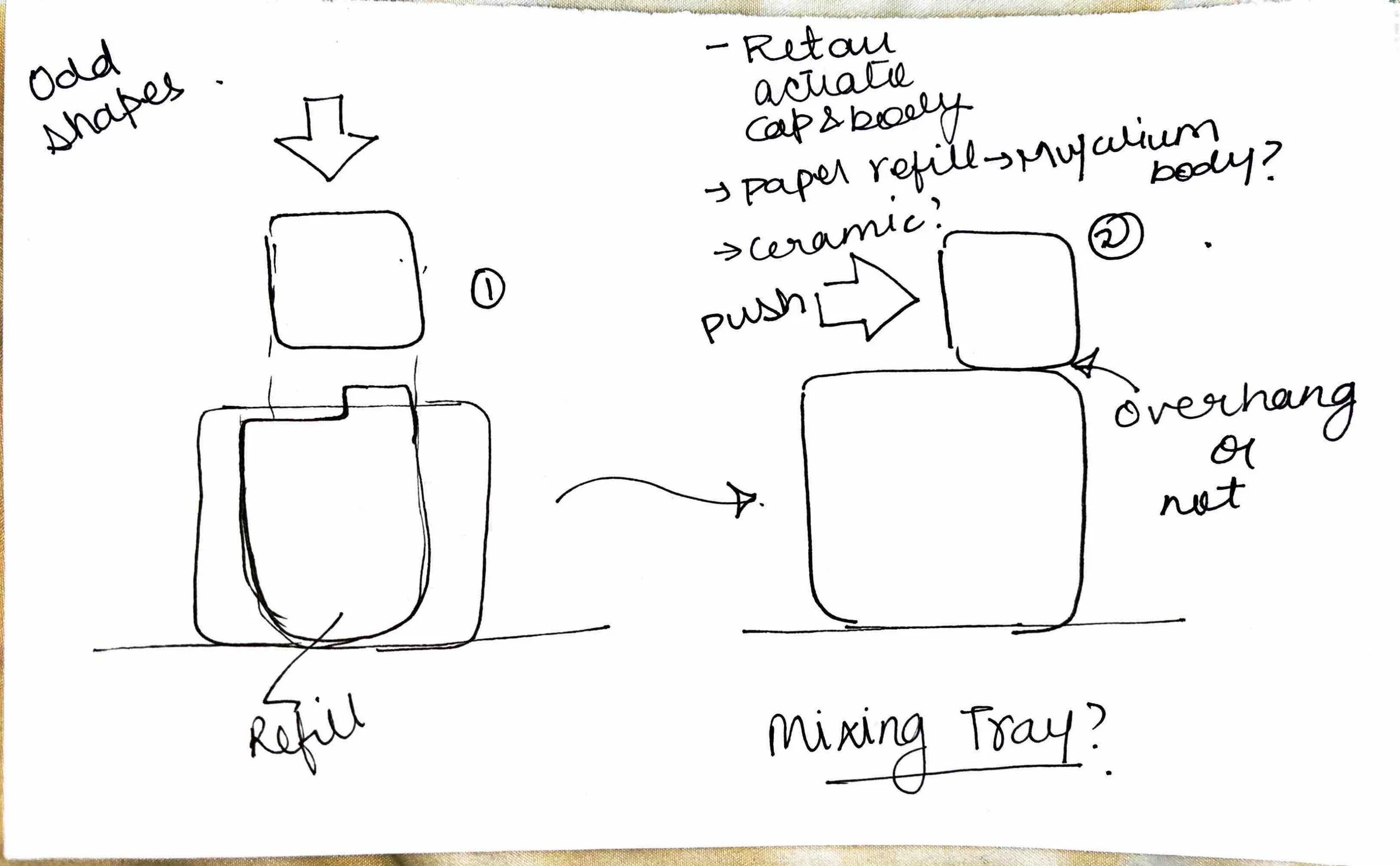

1.

2.

3.

4.

Trends & Mind-Maps

I conducted a trend study on the cosmetic industry to identify recurring themes, providing a foundation for my ideation process:

What’s the 2024 Trend?

Immersive

Consciously Crafted

Core Communities

“Well-designed Life”

What’s the upgrade?

Entertaining

Elevated functionalism

Not Cluttered

Luxe Material

What’s the interaction?

Sensory

Reactive

Tactile

Intuitive

The focus: Cosmetic tubes and their significance

2 out of every 5 cosmetic packagings

are tubes.

48 billion : 120 billion

Chosen for their ease of manufacturing, filling, and widespread familiarity, cosmetic tubes represent one of the oldest and most universally recognized forms of packaging.

Current User Scenario

>

>

<

<

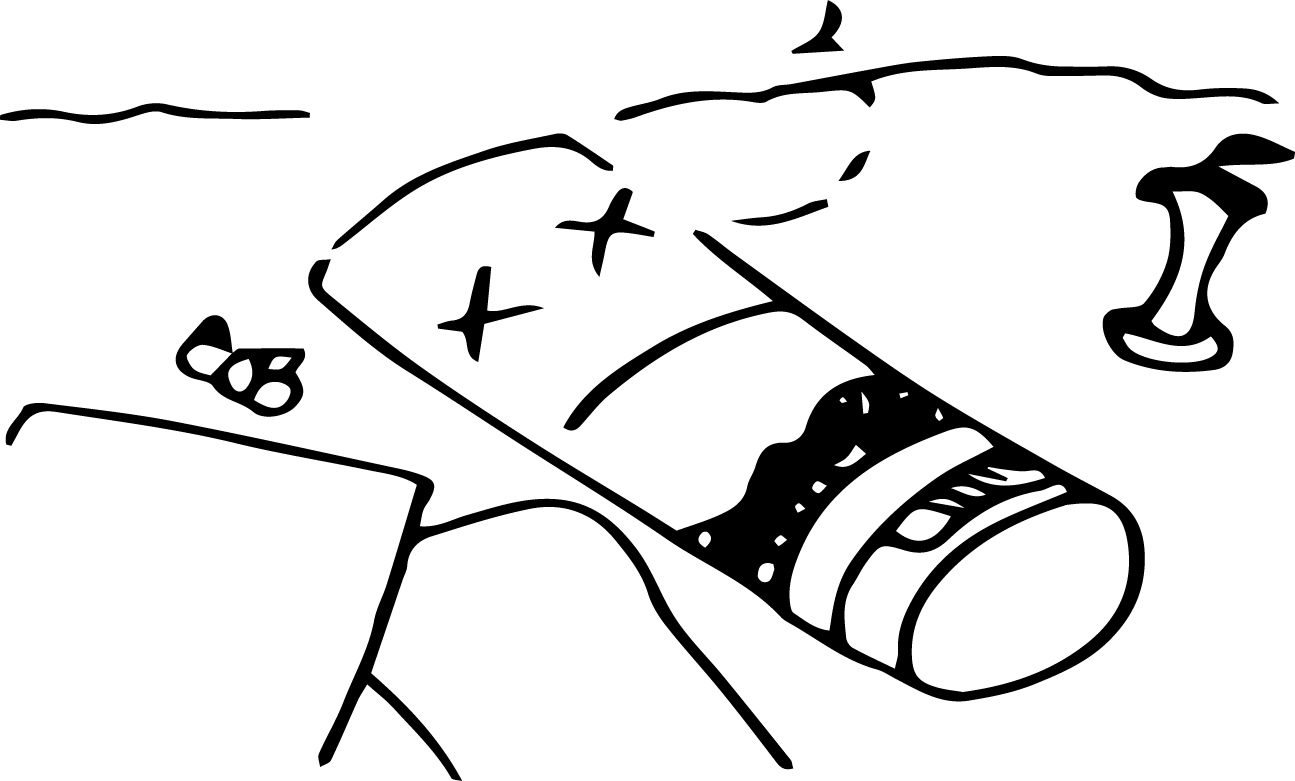

Many users toss out cosmetic tubes, thinking they're empty or lacking the time and tools to extract the last remnants. These partially used tubes, with product still inside, often end up in landfills because recycling systems reject them due to the residue.

This unfortunate cycle means valuable resources are wasted and the environment suffers from long-lasting waste.

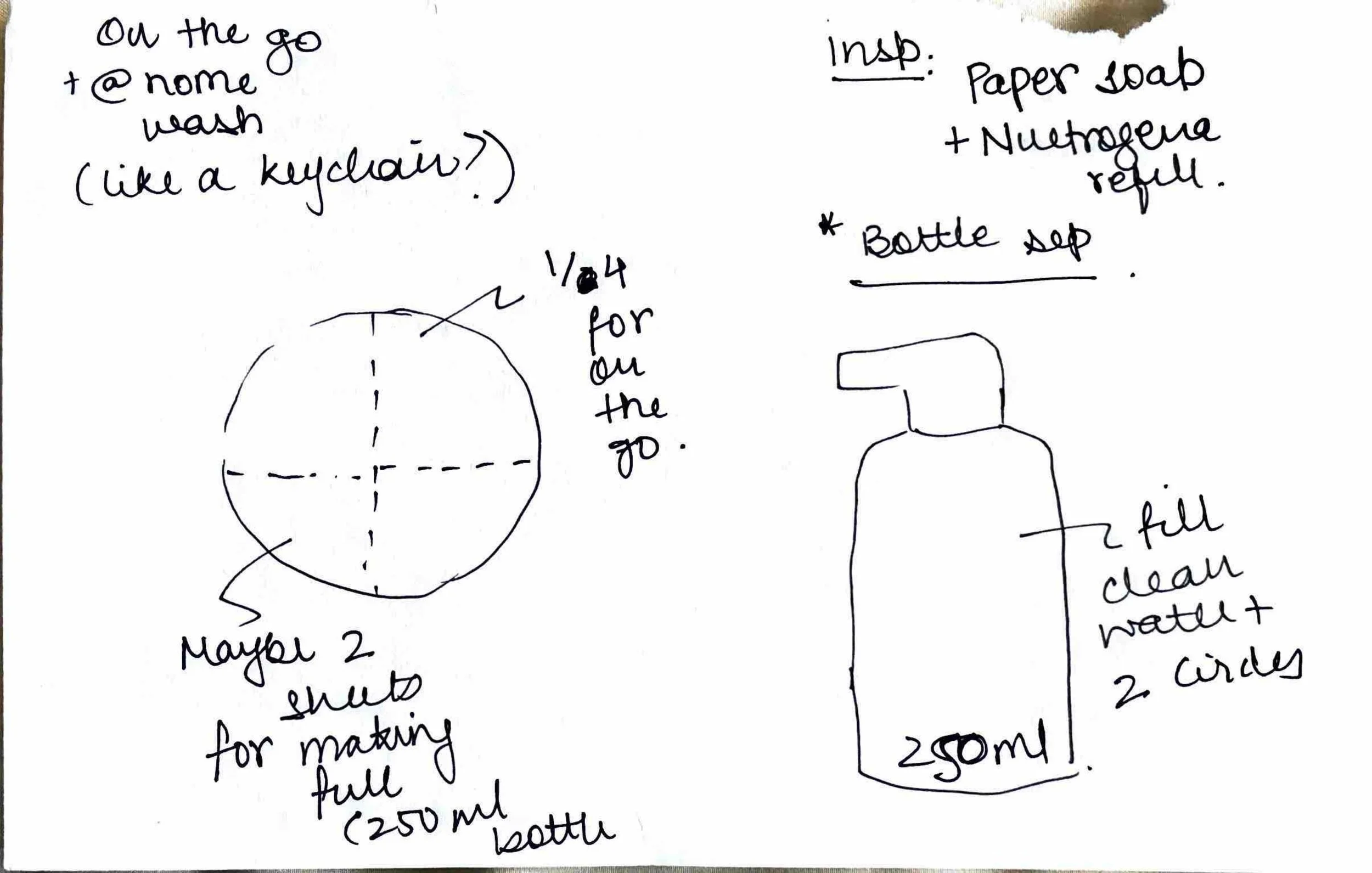

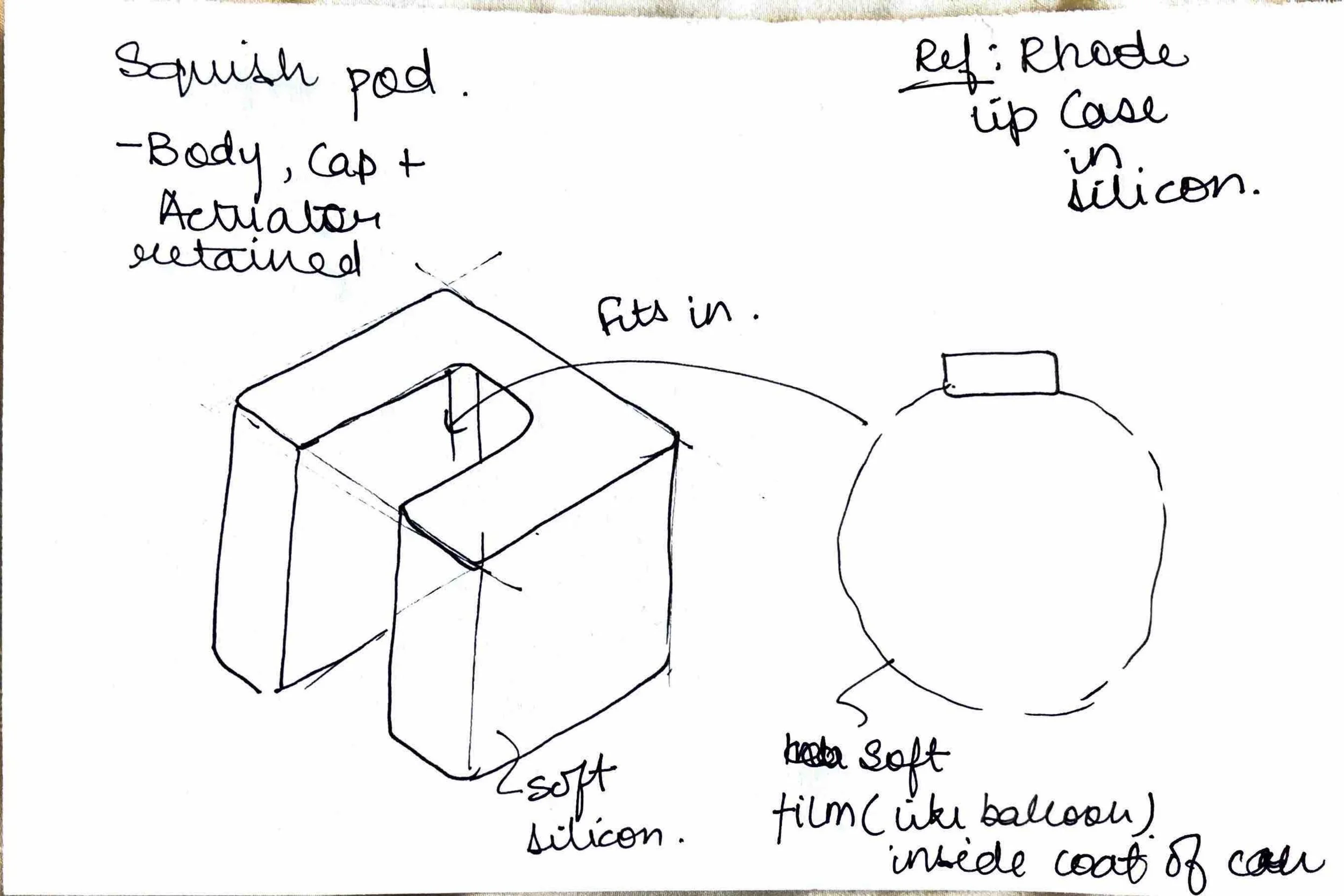

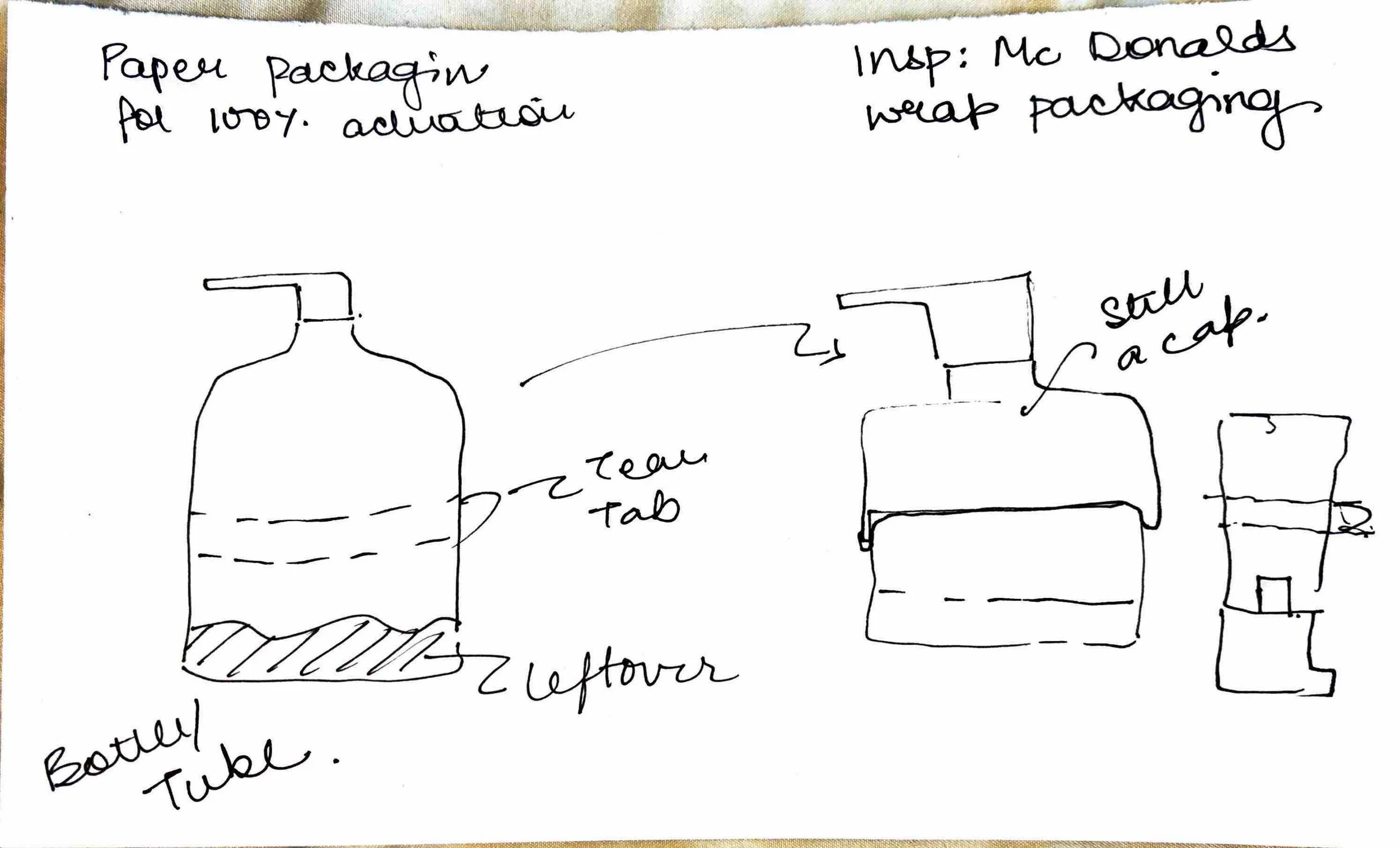

Ideation

How does the Last Drop Tube work?

>

>

<

<

Take a moment to locate the pull tab at the back of the tube.

With a gentle tug, tear along the seam, separating the tube's body from its base or "the raised-wall cup."

Once the two pieces are apart, grab a tissue or cloth and wipe out any remaining product inside.

This simple action ensures you're not wasting anything.

What's more, by separating the PET plastic body from the laminated paper base, you're making it easier for both materials to be recycled properly. By taking these extra steps, you're not only minimizing waste but also contributing to a more sustainable future.

Stakeholders x

Last Drop

Extracting the last drop from your cosmetic tube offers maximum usage with minimal effort, reducing waste significantly. It's a small action with big benefits for both you and the environment.

Recycling Systems

x

Last Drop

Good together, Better Apart

Tubes designed to help you extract the last drop make recycling easier by separating materials, contributing to a more efficient recycling process.

For the traditional tubes:

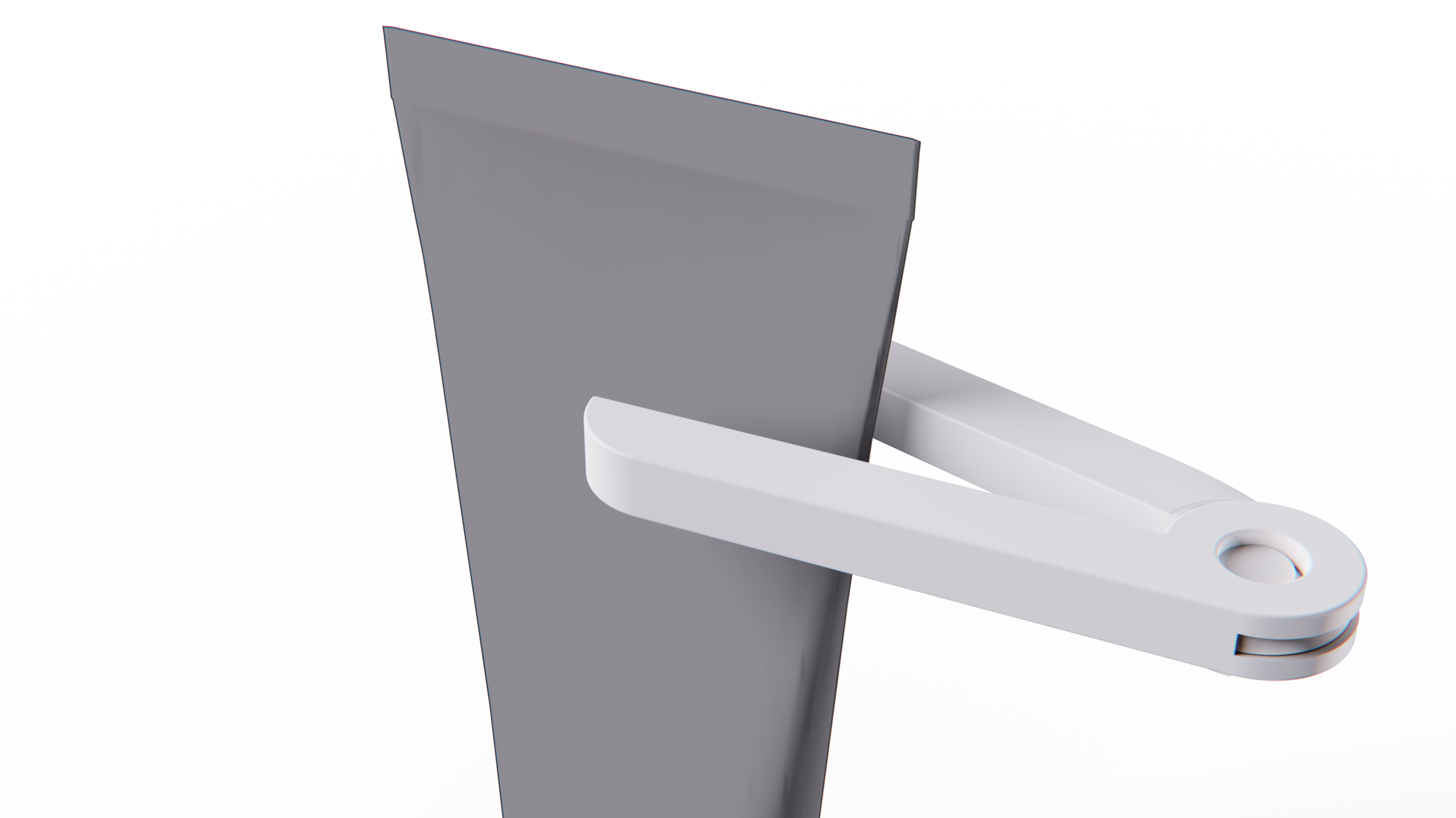

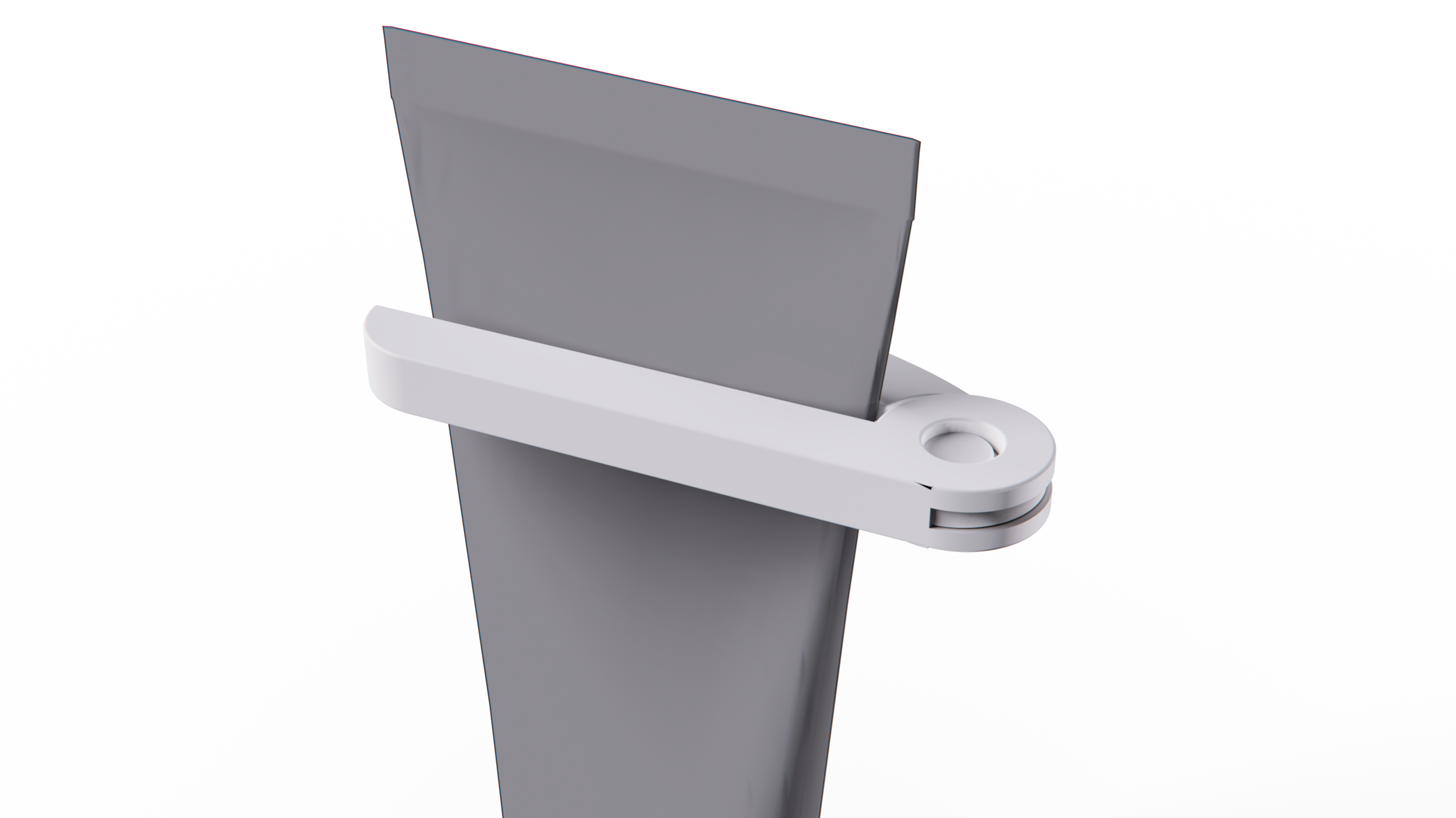

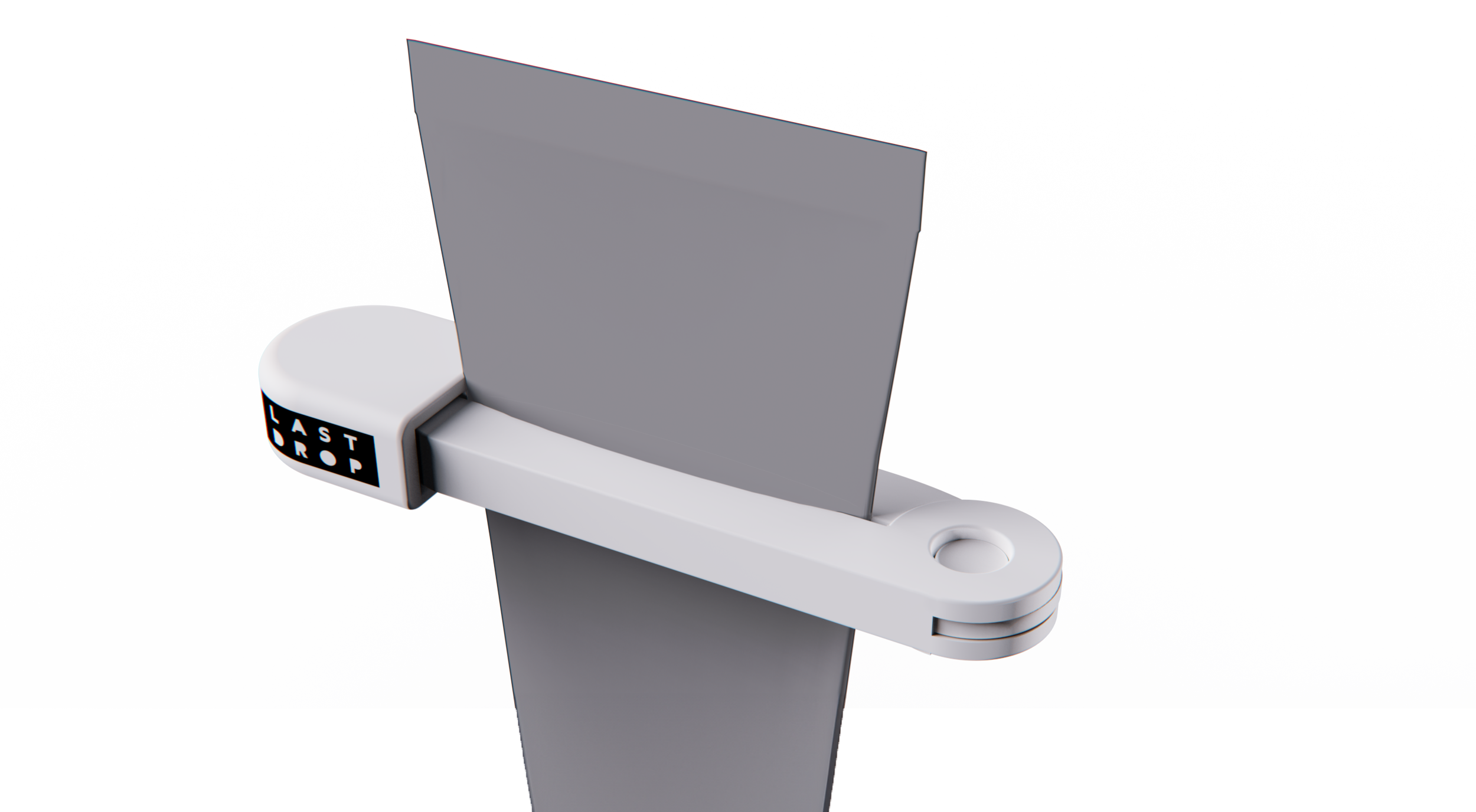

Last Drop Press

Engineered with Post-Consumer Recycled material, this eco-conscious accessory effortlessly fits most tube sizes, requiring little to no dexterity for maximum efficiency.

How to use: